Project Highlights:

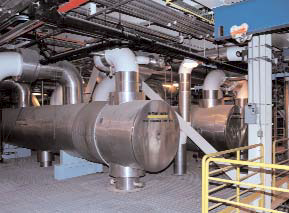

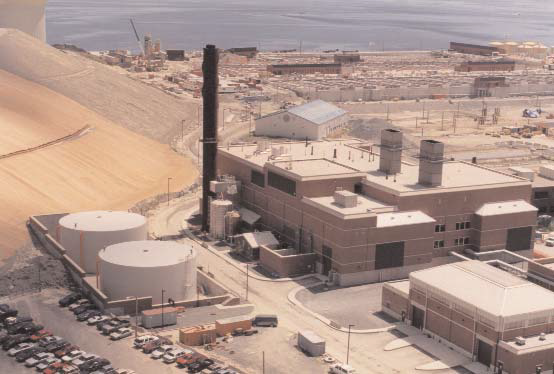

Two Zurn Dual Fuel fired boilers rated at 150,000pph MCR each delivering 620 psig/750 degrees F Superheated Steam to a Demag Delaval, Steam Turbine/Generator set rated at 18mw of electricity. The exhaust steam from the STG flows to two high temperature water heat exchanges that can provide up to 274 MM btu/hr of thermal energy to the Deer Island Treatment Plant.

Heat exchangers that provide both process heat and building heat. |

A Bailey Control based Distribution System was installed to operate the Power Plant. This system collects and integrates data from the Treatment Plant, fuel supply, boiler combustion and environmental readings to maximize the Deer Island Treatment Plant usage of the Power Plant while operating within safe and legal limits.

The Power Plant also houses two Turbo Power and Marine Combustion Turbine/ Generator sets rated at 26MW each running on No. 2 fuel oil supplied from two 750,000 gallon storage tanks located North of the plant.

J. F. white ensures all welding performed is in accordance with approved procedures. We have in our employ certified welders that have over 40 years of construction experience. this experience allows them to produce the highest quality welds. In addition, J. F. White employs a certified welding inspector who also serves as our QA/QC Corporate Manager. This project is a fine display of many of our work capabilities such as, coordination of barging material due to limited road access on the Island, installation of process pipe, electrical installation, concrete, set up of equipment. |